Biosafety Cabinets: Working Safely and Cleanly

A biosafety cabinet (BSC) is the primary workspace for cell culture and other sterile biological work.

Its purpose is to protect you, your samples, and the laboratory environment while you work. Whenever you handle cells, media, or other biological materials, the biosafety cabinet is where that work should happen.

Unlike a regular lab bench, a BSC actively controls airflow and filtration to create a clean, safe working area.

What Does a Biosafety Cabinet Do?

A biosafety cabinet provides three main types of protection:

- Personnel protection

Prevents you from being exposed to aerosols or splashes that may contain biological material. - Product (sample) protection

Keeps your cells and reagents sterile by filtering the air that flows over your work surface. - Environmental protection

Prevents potentially hazardous biological materials from escaping into the lab.

It accomplishes this using carefully controlled airflow and HEPA (High-Efficiency Particulate Air) filters, which remove ≥99.97% of particles 0.3 microns and larger.

Types of Biosafety Cabinets (Brief Overview)

Most cell culture work is performed in a Class II biosafety cabinet, which provides protection for personnel, product, and environment simultaneously.

- Class I: Protects personnel and environment, but not the sample

- Class II: Protects personnel, sample, and environment (most common)

- Class III: Fully enclosed, used for very high-risk work

If you work with cells, you will almost always be using a Class II BSC, typically Type A2.

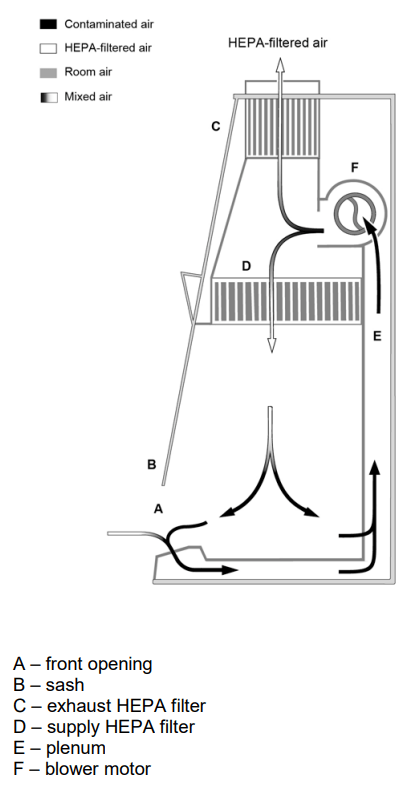

How a Biosafety Cabinet Works

At first glance, a biosafety cabinet may look like a hood with a glass front, but what’s happening inside is very precise:

- Room air is drawn in through the front grille

- Air flows downward in a smooth, laminar (non-turbulent) pattern

- HEPA-filtered air flows over your work surface to keep it sterile

- Air is continuously filtered before being exhausted or recirculated

This airflow pattern is what keeps contaminants out and hazardous aerosols in.

Main Parts of a Biosafety Cabinet

1. Sash (Glass Front Panel)

- Acts as a physical barrier between you and your work

- Must be kept at the correct height (marked on the cabinet) for proper airflow

2. Work Surface

- Usually stainless steel and easy to disinfect

- Often removable for cleaning spills underneath

3. Front and Rear Grilles

- Allow air to enter and circulate

- Must never be blocked, as this disrupts airflow and protection

4. HEPA Filters

- Clean incoming and outgoing air

- Critical for maintaining sterility and safety

5. Blower/Fan System

- Drives the airflow that makes the cabinet effective

6. Interior Lighting and UV (if present)

- Light helps visibility during work

- UV lights (when installed) are for decontamination only when the cabinet is empty and are not a substitute for proper cleaning

7. Control Panel

- Controls airflow, lighting, alarms, and UV (if equipped)

- Alerts users if airflow is unsafe

Why Technique Matters in a Biosafety Cabinet

A biosafety cabinet only works properly when it’s used correctly. Poor technique can disrupt airflow and compromise sterility or safety.

Good habits include:

- Working at least 4–6 inches inside the cabinet

- Keeping movements slow and deliberate

- Minimizing clutter inside the cabinet

- Organizing materials from “clean” to “dirty”

- Avoiding rapid arm movements in and out of the cabinet

Remember: the cabinet protects your work, but you are part of the airflow system.

Cleaning and Everyday Use

Before and after each session:

- Wipe down surfaces with appropriate disinfectant (e.g., 70% ethanol)

- Allow the cabinet to run for a few minutes before starting work

- Dispose of waste properly—do not let it accumulate

Never use a biosafety cabinet as storage. Extra items interfere with airflow and increase contamination risk.

What a Biosafety Cabinet Is Not

It’s important to clear up a common misconception:

- A biosafety cabinet is not a chemical fume hood

- Do not use volatile or toxic chemicals unless explicitly approved

- Fume hoods protect against chemical vapors; BSCs are designed for biological safety

Final Thoughts

Think of the biosafety cabinet as your primary safety zone for cell culture work. When used properly, it protects you, your cells, and your colleagues. Learning good technique early will save time, prevent contamination, and keep everyone safe.

Reflection Questions

- Why is it important to leave space along the air vents in the back of the biosafety cabinet?

- If you notice that a biosafety cabinet does not have a recent inspection sticker, should you use that biosafety cabinet?

- Why is it important to keep a biosafety cabinet uncluttered?

- Rick signed up to use the biosafety cabinet for cell work from noon to 2pm. When Rick arrives, he sees that Bobby has already set media and reagents out to to work in the biosafety cabinet. Rick checks the sign-up, but there is no error; Bobby did not sign up to use the biosafety cabinet.

Who has the right of way in the biosafety cabinet? - Why is it important to know who used the biosafety cabinet?

- At a minimum, how often should you decontaminate the biosafety cabinet with ethanol spray?

- What are the steps to starting up the biosafety cabinet for cell culture work?

- Paraformaldehyde (PFA) is a corrosive liquid that scientists frequently use to fix cells in cell culture. Your mentor’s protocol tells you to work with PFA in a fume hood. Should you fix the cells in the biosafety cabinet? Why or why not?

- The vacuum line in your biosafety cabinet has poor suction. What are three reasons that this might be happening?

- What are some acceptable items to leave in the biosafety cabinet between users?

- While performing cell culture, you need to turn off an incubation timer that is outside the hood. What should you do before you continue working in the biosafety cabinet?

- What are some materials that you might bring into a biosafety cabinet?

- What are the steps to shutting down the biosafety cabinet?

Leave a comment